Industrial Wind Turbine For Sale

Wind Technik Nord WTN250 – 250kW

Immediately available – already dismantled

General Overview

- Model: 2010 WTN 250 WindTechnik Nord

- Commissioned: 2014 – only 11 years in operation

- Rated power 250kW (50Hz)

- Rotor diameter 30m

- Tower Height: 40m

- Full Service history available

- Location: Northern Ireland

- Reason for Sale: Repowering

Harnessing two decades of expertise in wind turbine innovation, the WTN 250 is known for its enduring design and outstanding yearly generation excellence. The WTN 250 embodies its predecessors’ trusted, sturdy build while incorporating the latest advancements in wind technology. Engineered by German WindTechnik Nord, this turbine is tailored for high-velocity wind conditions typical in elevated areas, ensuring peak energy production and output.

Wind Technik Nord WTN250

Click on the pictures to see full view

The WTN 250’s consistent operational availability and production capacity, coupled with superior manufacturing standards, position it as an economically favorite option in the second-hand market. Its cost-effectiveness, and a high return on investment, underscores its appeal as a sound financial choice for 1st-time energy investors.

Rotor

- Cut-in 4m/s

- Rated wind speed 14m/s

- Cut-out 25m/s

- Type Three-bladed

- Diameter 30 m

- Swept area 707 m2

- Rotational speed 26/40 rpm

Blades

- Type: LM 13.4

- Material: glass-fibre

- Length 13,39m

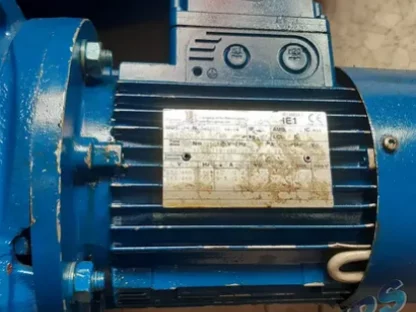

Generator

- Type: Asynchronous

- Rated output: 50/250kW

- Voltage: 415V

- Frequency: 50Hz

Gearbox

- Type: Spur

- Ratio: 1:37.777

- Stages: 3

Tower

- Type: Steel, tubular – 40 metre -three sections

Brake system

- Aerodynamic Brakes: Tip brakes

- Activation: Hydraulic

- Mechanical Brakes: disc brakes

- Activation: Mechanical

DOWNLOAD Wind Technik Nord WTN250 Noise Spec

IMPORTANT NOTES

- Viewings are arranged only if a signed LOI (Letter of Intention) has been received.

- Time wasters and tyre kickers will strictly not be accommodated!

Call us today on ☎ +44 77 888 66 846

MWPS Global offers expert assistance with dismantling, international shipping, transportation, as well as comprehensive refurbishment and upgrade services at competitive rates.

Partnering with skilled remanufacturers, refurbishers, and machinists, MWPS Global ensures all re-manufactured equipment meets:

- Original manufacturer specifications

- Adheres to our stringent quality standards.

- Each refurbished wind turbine is fully disassembled, meticulously inspected, and cleaned.

- Our experienced refurbishment partners assess the turbine’s condition, replacing all worn components.

- Critical moving parts are renewed to new or superior standards.

- The controls, gearbox, hub, generator, and hydraulic systems are thoroughly reconditioned or replaced as needed.

- Every refurbished turbine is supplied with a detailed technical report documenting the refurbishment process.

Additional Information Wind Technik Nord WTN250

Blades & Rotor

The WTN 250 features a 3-blade upwind rotor with stall regulation for enhanced efficiency. Blades are made from reinforced polyester with centrifugal fail-safe tip brakes. The rotor has a 30 m diameter, 13.4 m blade length, and a swept area of 707 m², rotating at 40 rpm.

Hub

Made of cast steel (GGG 40.3), the hub attaches to the rotor shaft flange. Blade pitch is adjustable via oval holes in the blade flanges.

Main Shaft & Bearings

The forged alloy steel main shaft is supported by two grease-lubricated bearings for smooth, quiet operation and reliable load transfer.

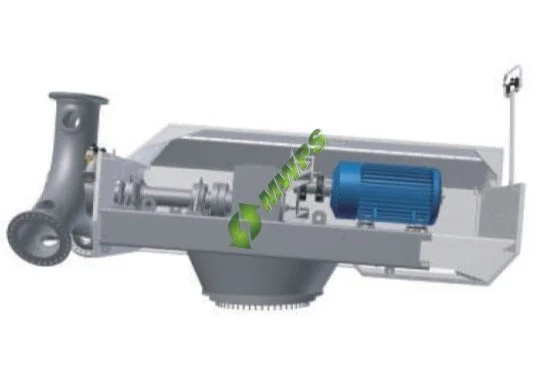

Gearbox

A heavy-duty three-stage helical gearbox converts 40 rpm rotor speed to 1,500 rpm for the generator, with a 37.8:1 gear ratio and oil lubrication for durability.

Wind Technik Nord WTN250 Graphic

Coupling

An elastic coupling transmits power from the gearbox to the generator, preventing vibrations from reaching the generator bearings and extending their lifespan.

Brakes and emergency brake system

The turbine features two independent fail-safe braking systems. Blades have safety tip brakes that activate simultaneously, complemented by a disc brake operated by hydraulic calipers triggered by voltage loss. In emergencies, both systems engage independently via a centrifugal-activated hydraulic valve.

Generator

The generator is a pole-changing asynchronous machine delivering 250 kW at 1,500 rpm and 50 kW at 1,000 rpm, running on 400 VAC with external ventilation.

Yaw-System

Yaw System

The WTN 250’s advanced dual-gear yaw system eliminates backlash and includes damping and braking to reduce yaw forces. It’s ideal for wind farms, preventing cable twisting with automatic untwisting and an extra twisted cable safety switch.

Wind Technik Nord WTN250

Nacelle

Constructed from hot-dip galvanized welded steel beams, the nacelle supports the main components and connects to the tower via a yaw ring. Access is through an internal ladder, with galvanized steel covers.

Tower

A specially designed lattice tower fits all turbine parts into a 40 ft container for cost-effective global transport. A bolted tubular tower is also available. Standard hub height is 50 m for reduced turbulence and longer turbine life, with a 30 m option for height-restricted sites. The microprocessor control system is housed at the tower base, secured by a lockable door. Safety equipment includes a belt and lifeline for secure climbing.

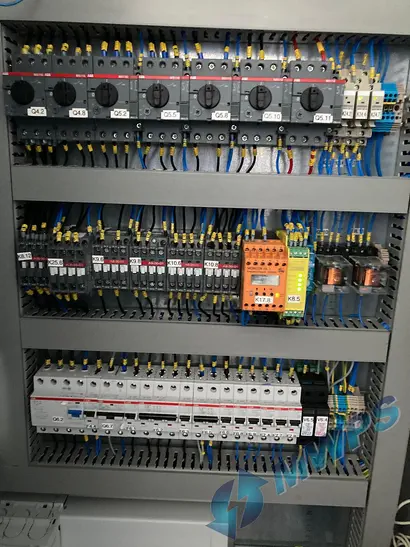

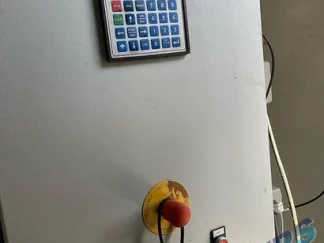

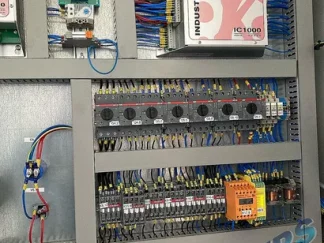

Control panel

A microprocessor-based controller governs turbine operation, logs performance and safety data, and supports connection to a central farm management system for remote monitoring. When not networked, the same data are viewable on a local display. The controller continuously monitors sensors and safety functions, including:

- – Grid control of Voltage, Frequency Phase equality

- – Overspeed control on the rotor that activates the disc brake

- – Thermal sensor in generator

- – Vibration sensor

- – Automatic untwisting of cables

- – Thermal relay for yaw gear motor

- – Automatic stop for worn brake pads

- -Automatic start-up in the event of grid failure

- – Self-diagnostic in case or failure. A display indicates a failure code.

- – Generator speed

- – Rotor speed

- – Yawing

- – Over speed

Grid connection is managed via thyristors for soft synchronization on all three phases; phase compensation in the main panel enables a power factor above 0.9. All electrical components are protected against lightning.

Wind Technik Nord WTN250

If this advert was of interest, then don't forget to subscribe!