Showing 265–276 of 329 resultsSorted by latest

-

SEEWIND 25 – 132kW Wind Turbine – Good Condition

£29,425 -

Südwind N3127 – 270kW Wind Turbine Sale

£37,500 -

FUHRLANDER FL250 Wind Turbines for Sale

£30,500 -

LAGERWEY 250-27 – 250kW Wind Turbine For Sale

£65,475 -

ENERCON E16 – 55kW – Used Wind Turbines For Sale

£25,050 -

VESTAS V66 Wind Turbines Wanted

£0 -

ECOTECNIA 20 – 150kW Wind Turbine Wanted

£0 -

NORDTANK Wind Turbines 150kW XLR For Sale

£30,750 -

ENERCON E32/33 – 330kW Wind Turbine For Sale

£30,500 -

MICON M450 – 250kW Used Wind Turbine For Sale

£37,500 -

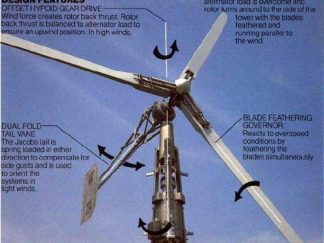

JACOBS 31/20 – 20kW Wind Turbine for Sale

£8,500 -

MICON M300 – 55kW Used Wind Turbine For Sale

£25,050